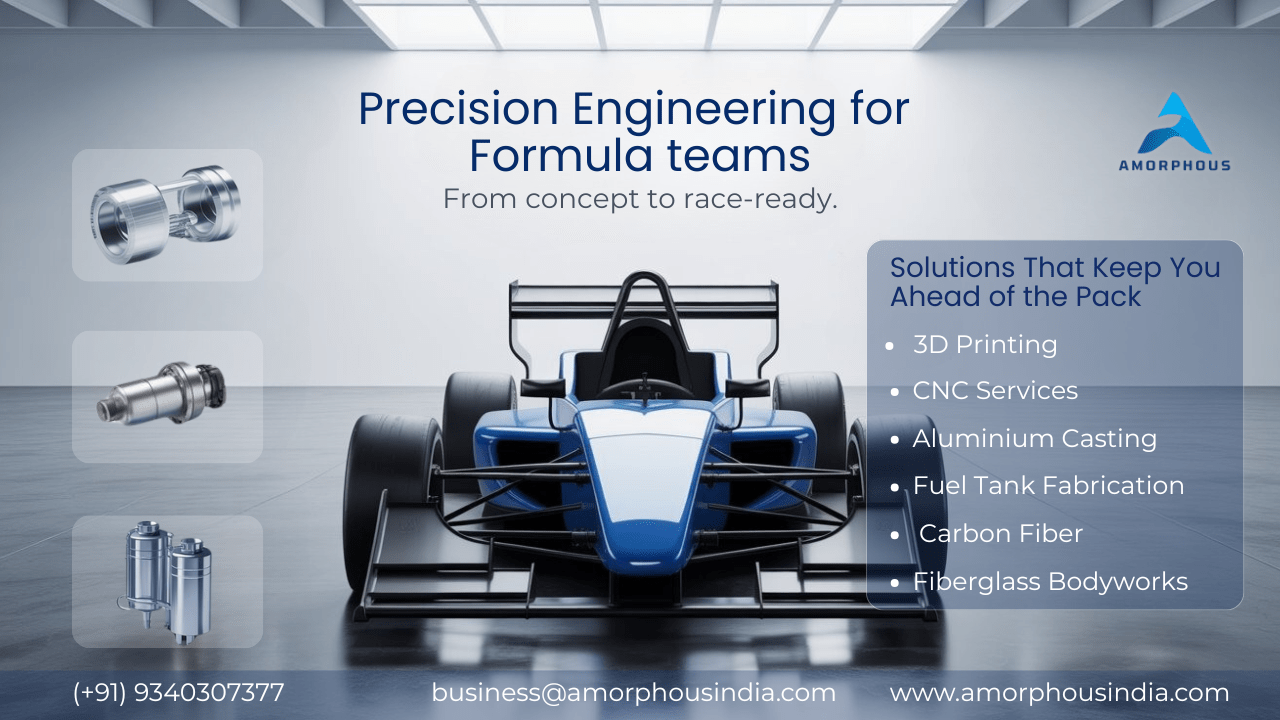

India’s motorsport landscape is experiencing an unprecedented transformation. From Formula Bharat to SAE SUPRA competitions, engineering students across the nation are pushing the boundaries of innovation, design, and manufacturing. At the heart of this revolution lies advanced manufacturing technology—and Amorphous India is proud to be powering the next generation of automotive engineers.

Beyond Traditional Manufacturing: Where Innovation Meets Precision

Our recent collaboration with a leading Formula Bharat team exemplifies this transformation. They approached us with a complex suspension upright design that required both lightweight construction and exceptional strength. Using our integrated approach—combining topology optimization with advanced manufacturing—we delivered:

-

45% weight reduction through topology-optimized design

-

Reduced production time from 3 weeks to 5 days

-

Zero material waste through precision CNC machining

-

Perfect fit and finish ready for competition

The result? Their car not only passed technical inspection but also achieved a podium finish in the dynamic events.

The Technology Behind the Success

Laser Cutting: Precision Without Compromise

-

Our fiber laser cutting systems work directly from CAD files, ensuring every cut matches your design specifications exactly. Whether it’s chassis brackets, aerodynamic elements, or custom fuel tank components, the process eliminates human error while delivering clean, precise cuts with minimal heat-affected zones.

CNC and VMC machining: Where Strength Meets Precision

-

For critical components like suspension uprights and drivetrain parts, our CNC and VMC capabilities deliver production-grade quality with tolerances as tight as ±0.05mm. Our multi-axis machines can handle complex geometries in a single setup, reducing production time and maintaining consistency across components.

3D Printing: Rapid Innovation at Scale

-

From rapid prototyping to end-use parts, our 3D printing services enable teams to iterate quickly and produce complex geometries impossible with traditional manufacturing. Whether it’s custom air ducts, mounting brackets, or lightweight structural components, additive manufacturing opens new possibilities for innovative design.

Carbon Fiber and Composites: Lightweight Performance

Looking Ahead: Trends Shaping Manufacturing in 2025

As we move deeper into 2025, several key trends are reshaping how we approach manufacturing for motorsport applications:

Digital Integration: CAD-to-manufacturing workflows are becoming seamless, reducing time from design to finished part while maintaining perfect accuracy.

Sustainable Manufacturing: Advanced manufacturing techniques minimize material waste and energy consumption—critical considerations for environmentally conscious racing programs.

Customization at Scale: Every racing team has unique requirements. Modern manufacturing technology allows us to deliver highly customized solutions without the traditional cost penalties of small-batch production.

Quality Without Compromise: Real-time monitoring and precision control systems ensure consistent quality across all components, regardless of complexity or production volume.

The Amorphous Advantage: More Than Manufacturing

What sets Amorphous India apart isn’t just our technology—it’s our understanding of what student racing teams need to succeed. We’ve worked with teams from their initial concept sketches through to race day, providing not just manufacturing services but engineering partnership.

Our approach combines:

-

Technical expertise in motorsport-specific applications

-

Rapid turnaround to meet tight competition deadlines

-

Cost-effective solutions designed for student budgets

-

Comprehensive support from design optimization to final assembly

Building the Future, One Component at a Time

Every part we manufacture represents more than just metal and plastic—it’s the foundation for tomorrow’s automotive innovations. The students we work with today will become the engineers, designers, and leaders who shape India’s automotive future.

When a Formula Bharat team trusts us with their suspension components, or a SAE SUPRA team relies on our precision machining for their drivetrain, we’re not just manufacturing parts—we’re enabling dreams, supporting innovation, and contributing to India’s growing reputation as a hub for engineering excellence.

Ready to Transform Your Project?

Whether you’re designing your first racing car or refining a championship-winning formula, Amorphous India has the technology, expertise, and passion to bring your vision to life. From initial concept to podium finish, we’re your manufacturing partner for success.

Contact us today to discover how precision manufacturing can accelerate your project from concept to competition-ready reality.