Introduction

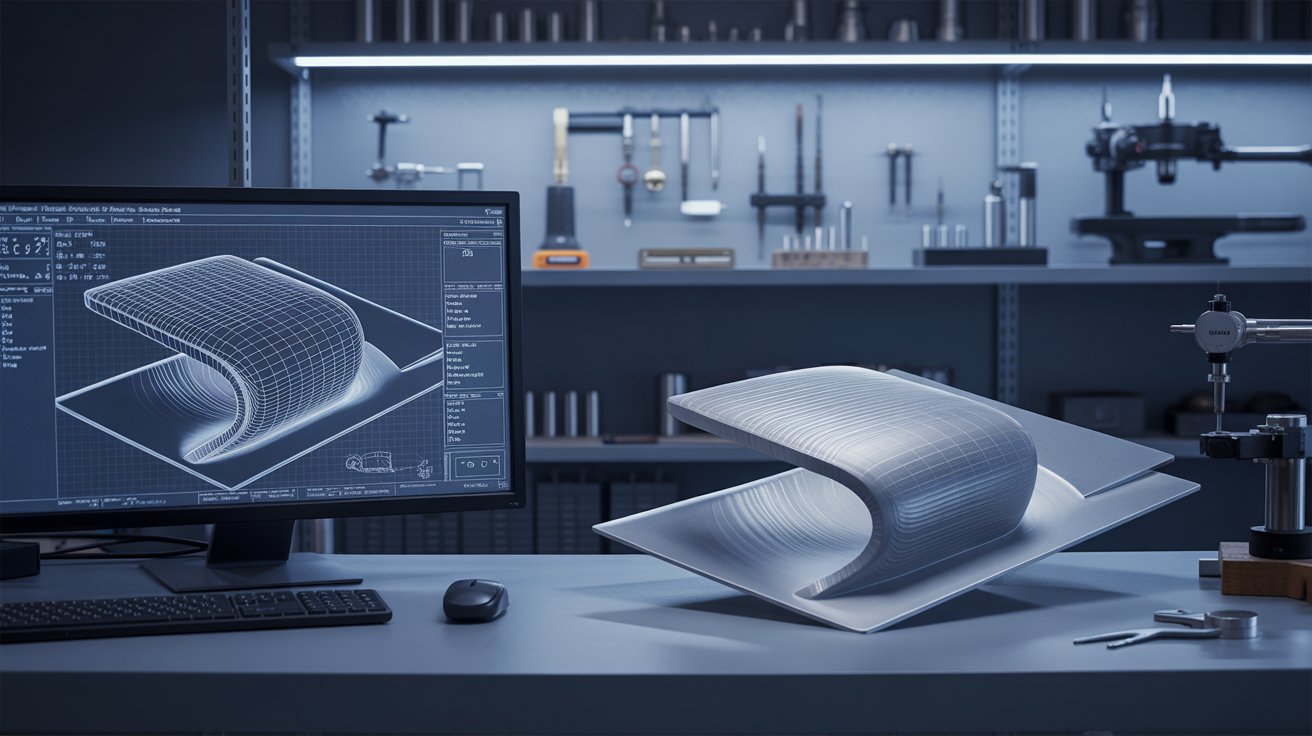

In today’s competitive engineering and manufacturing landscape, the speed at which an idea transforms into a functional product often determines its success. Prototyping plays a critical role in this journey — bridging the gap between concept and production. At Amorphous India, prototyping is not just a step in the process; it is the foundation of reliable, scalable product development.

Why Prototyping Matters in Product Engineering

Prototyping allows engineers and designers to validate ideas early, reducing uncertainty and costly revisions later in the development cycle. By creating physical representations of digital designs, teams gain real-world insights that cannot be achieved through simulations alone.

Key benefits include:

- Early detection of design flaws

- Improved communication between design and manufacturing teams

- Faster decision-making

- Reduced development risk and cost

Types of Prototyping Used in Modern Manufacturing

1. Rapid Prototyping (3D Printing)

Rapid prototyping enables quick iteration and testing of form, fit, and function. It is ideal for early-stage validation, ergonomic studies, and concept demonstration.

2. Functional Prototyping (CNC Machining)

CNC machining is used when high dimensional accuracy and material-specific testing are required. It helps validate tolerances, strength, and real-world performance.

3. Low-Volume Production (Vacuum Casting)

Vacuum casting bridges the gap between prototyping and mass production. It allows small batches of production-quality parts with excellent surface finish and material properties.

The Role of Prototyping in Design for Manufacturing (DFM)

One of the most valuable outcomes of prototyping is its role in Design for Manufacturing. By testing prototypes early, teams can:

- Optimize part geometry

- Improve assembly efficiency

- Select appropriate materials

- Reduce tooling complexity

This ensures a smoother transition from prototype to production.

Industry Applications

Prototyping is essential across multiple industries, including:

- Medical Devices: Ergonomics, patient safety, and regulatory readiness

- Automotive & Aerospace: Precision, performance, and reliability

- Industrial Products: Structural integrity and long-term durability

- Consumer Products: User experience and visual appeal

Conclusion

Prototyping is no longer optional in modern product development — it is essential. It reduces risk, improves quality, and accelerates innovation. By investing in the right prototyping strategy, companies can move confidently from concept to reality.

At Amorphous India, we continue to support innovators and manufacturers by transforming ideas into reliable, engineered solutions.